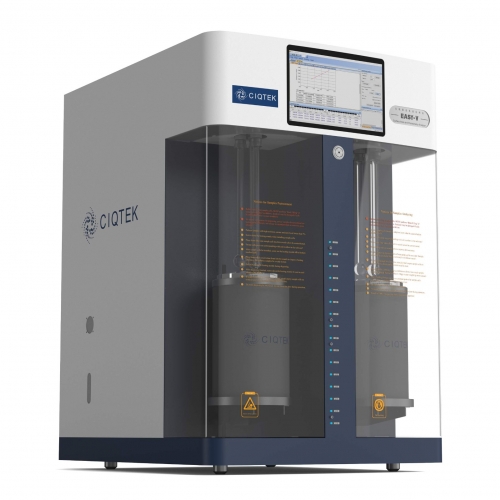

♦ Embedded test computer, safe and stable. 10-inch capacitive touch screen, tablet control experience.

♦ The ball screw integrated lifting system, controlled by the stepper motor, overcomes the shortcomings of common screw types easy to jam, and so on.

♦ 2 sample pipe joints and 1 P0 pipe joint per test module. P0 pipe can be used for specific surface area testing in a cost-effective manner.

♦ Independent 2 sample processing ports can be performed simultaneously with sample testing to improve testing efficiency.

♦ 4L stainless steel inner Dewar bottle overcomes the fragile defect of glass Dewar bottle, and high thermal insulation ensures continuous test requirements for more than 72 hours.

Digital pressure measurement and data acquisition system

- The pressure and temperature sensor with digital output has twice the accuracy of similar products with analog output and stronger anti-interference ability.

- Industrial standard RS485 or RS232 communication mode. Sensors are added on demand on the communication bus, with high scalability.

- The high-precision digital pressure sensor has a pressure output resolution of 1Pa, which is conducive to higher testing accuracy compared to the 4pa resolution commonly used in the same industry.

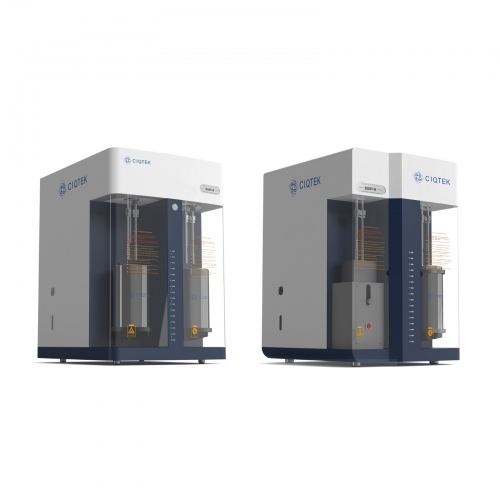

Integrated vacuum pipeline system

- The integrated container vacuum pipeline system can effectively reduce the pipeline connection points and improve the ultimate vacuum degree of the system.

- The compact integrated system improves temperature uniformity and reduces the dead volume space, which can effectively improve test accuracy.

- Panel type parts installation method, spare parts can be disassembled independently, which is convenient for installation and maintenance.

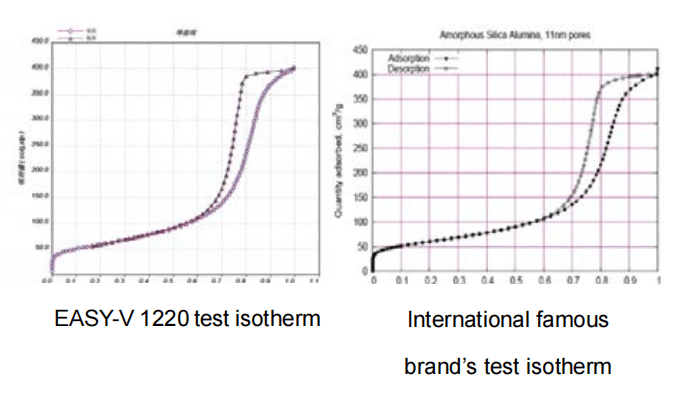

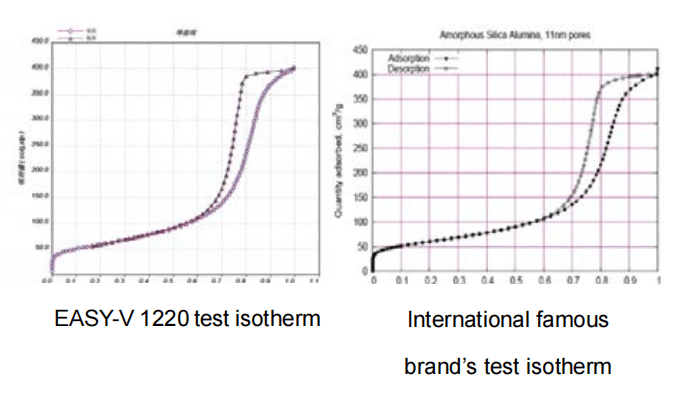

World-leading data accuracy and authority recognition

- Adopt the same instrument testing and acceptance criteria of world-leading brands and ensure the test data is in line with international standards; the measurement error is dynamically eliminated by the software during the test, with no secondary error elimination operation of data after the testing, ensure the consistency and reliability of test results by different operators.

- The product's technology has obtained the certificate of scientific and technological achievements from the China Machinery Industry Federation, reaching the international leading level. The test data has been certified by several authoritative national measurement institutes and obtained the measurement recognition certificate.

- A number of products have entered the testing laboratories of European and American universities and have been highly recognized by customers.

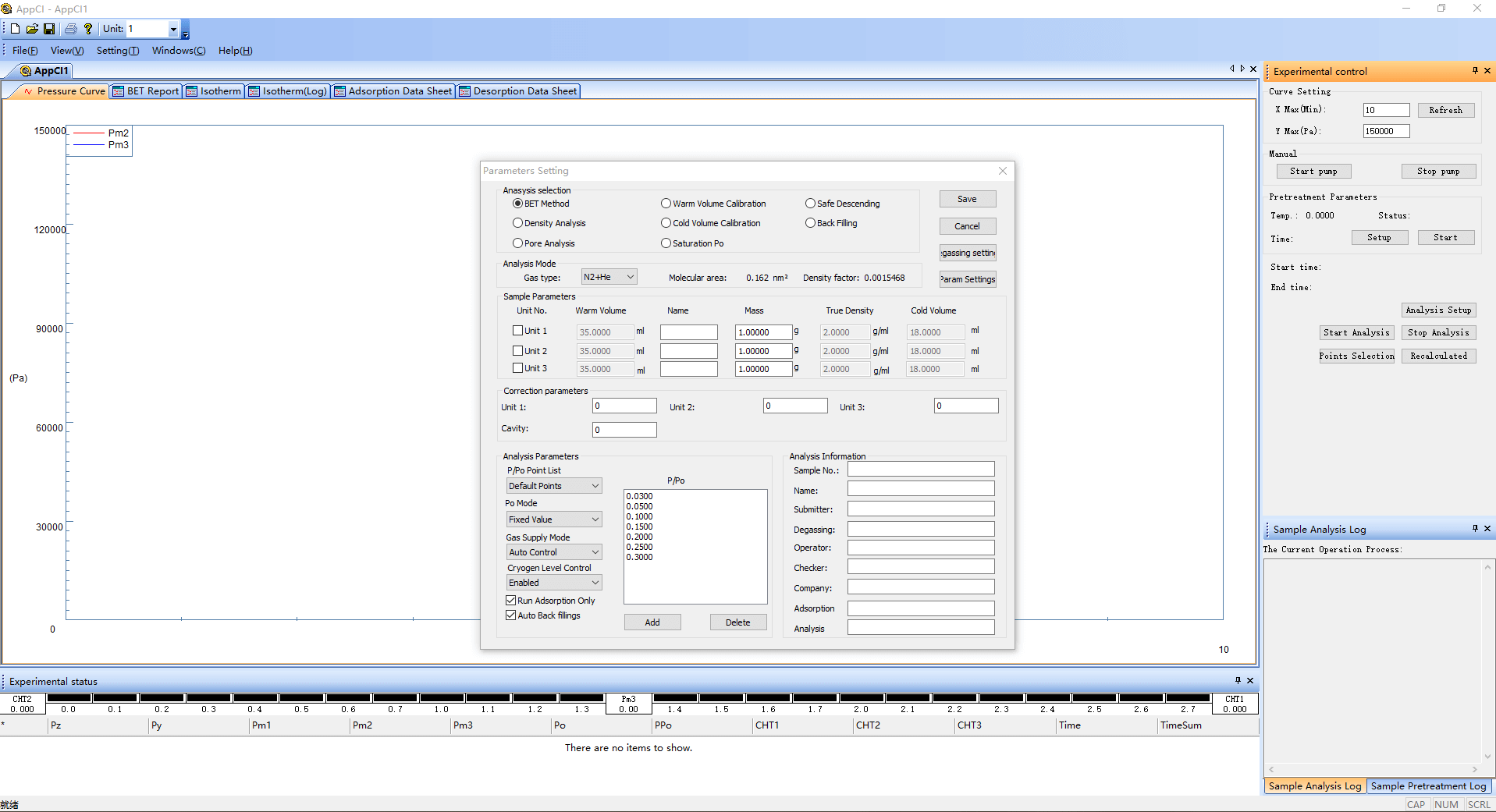

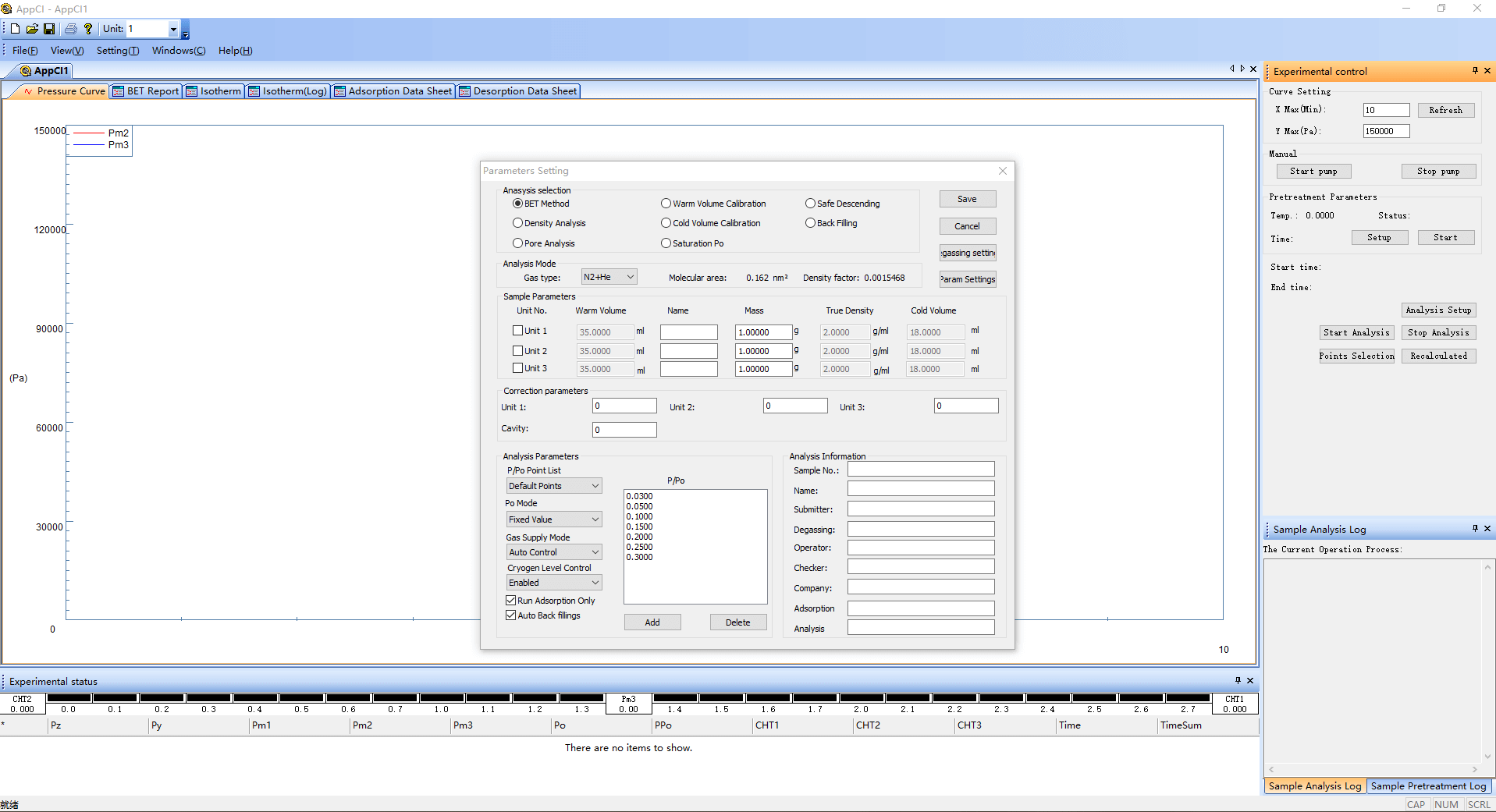

Intelligent testing software

- The sample processing function is integrated into the test software to realize the complete automation. Sample processing time, different processing temperature combinations, sample processing delay, and other functions can be set flexibly, which can realize automatic sample processing at night and improve testing efficiency.

- Data processing software has perfect functions and easy operation, a user-friendly interface, detailed test data records, and a variety of perfect data processing modes.

- The test software adopts the Net software development platform of the advanced Microsoft technology with strong compatibility that can automatically be compatible with all and the future Windows operating system.

Battery Materials

Graphite, lithium iron phosphate, lithium manganate, lithium cobalt oxide, ternary materials, and other positive and negative materials.

Petrochemical Industry

Carbon black, white carbon black, titanium dioxide, alumina, molecular sieve catalyst, resin, carbon fiber, etc.

Medicine

Montmorillonite powder; Magnesium stearate, micropowder silica gel, talc and other lubricants; Diluents such as starch and sugar; Aluminum hydroxide and other pharmaceutical excipients.

Environmental protection materials

Pine, activated carbon, bamboo charcoal, chemical carbon, zeolite molecular sieve, etc.

Nanomaterials

MOF materials, carbon nanotubes, graphene, etc.

Other powder and granular materials

Magnesium oxide, zirconia, calcium oxide, metal powder, ceramics, mineral powder, etc.

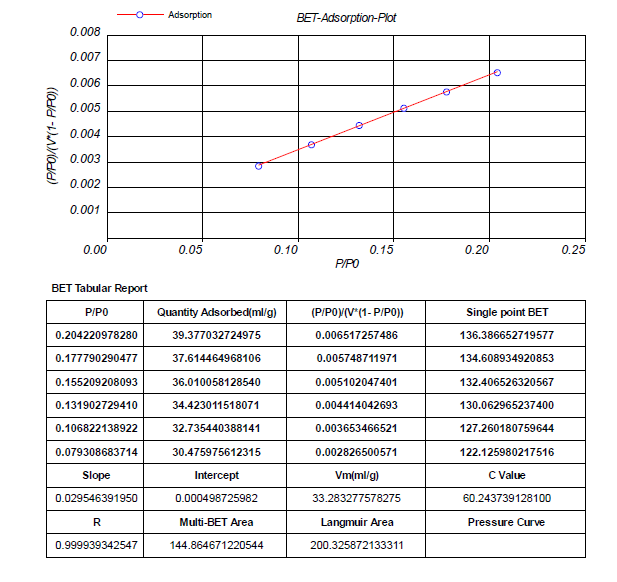

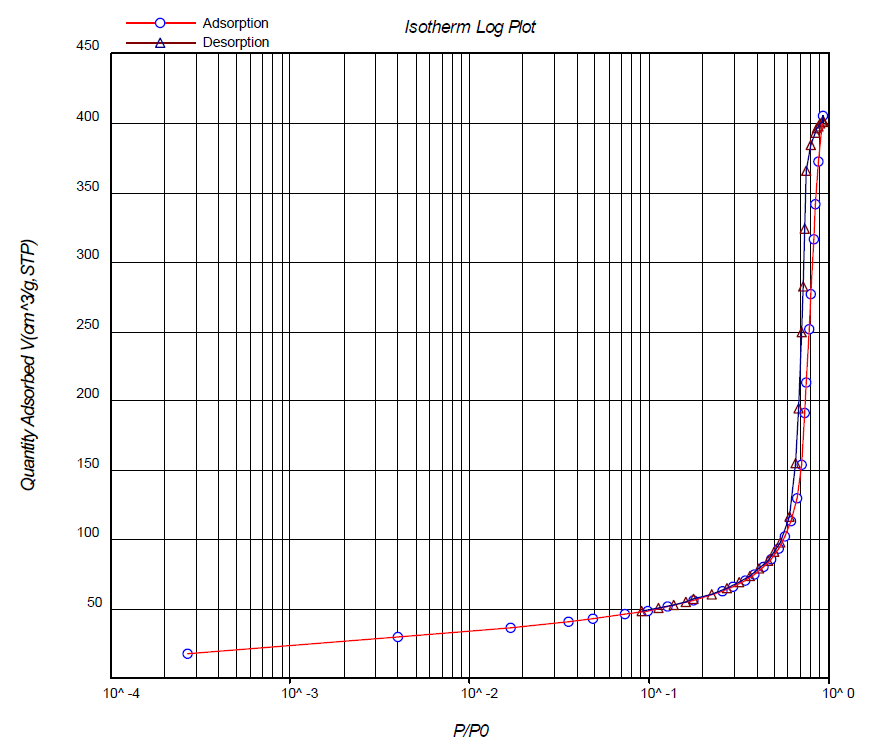

> Test function:

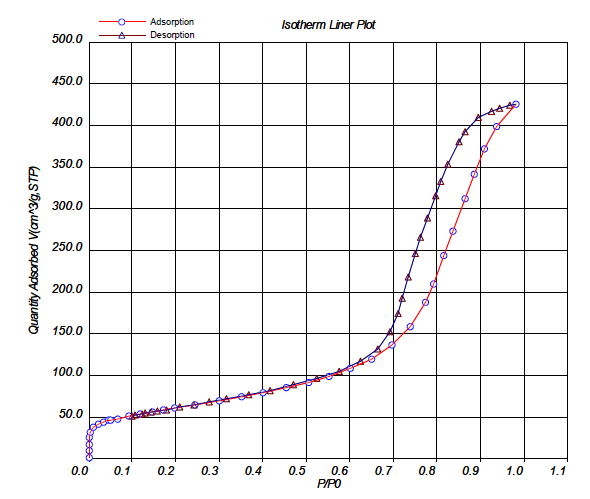

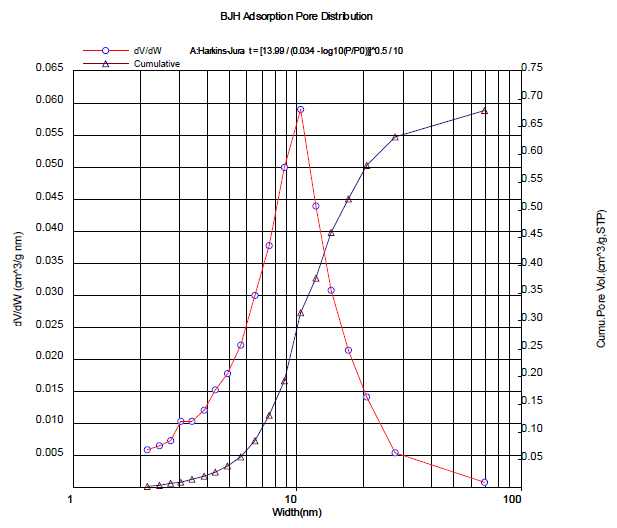

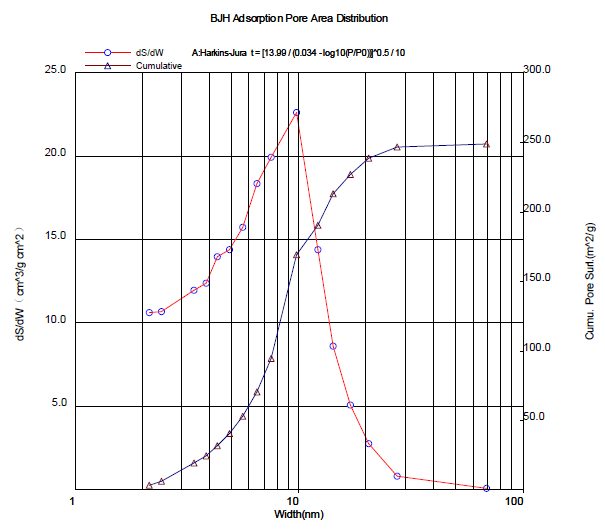

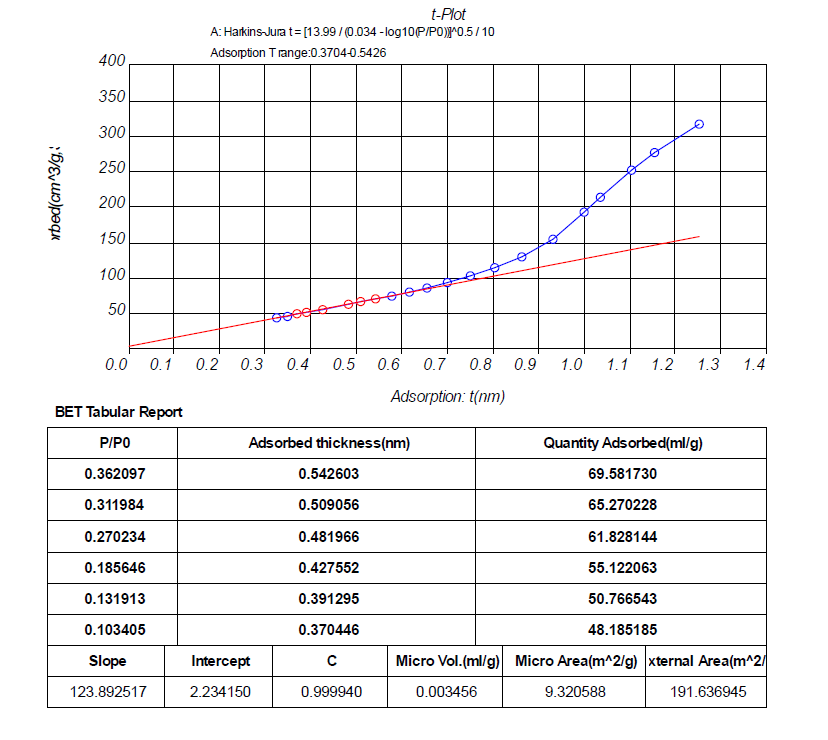

Static volumetric principle, adsorption/desorption isotherms measurement, single and multi-point BET method, Langmuir method, BJH total pore volume and pore size distribution analysis, DR and DA filling theory, t-plot external surface area measurement, true density measurement; Powerful online data analysis system and specific surface area and pore size distribution test system to ensure more stable and accurate test data.

> Test ranges:

0.0005 (m2/g)~unknown upper limit (specific surface area); 2 nm - 500 nm.

> Test accuracy:

Specific surface area repeatability error ≤±1.0%.

> Sample number:

Two samples were tested at the same time and the two samples' degassing treatment, sample testing system, and sample processing system are independent;

Sample testing and sample processing can be carried out simultaneously, avoiding the contamination of the test pipeline, further ensuring the accuracy of the test, and improving the service life of the instrument.

> Test modes:

Integrated "Single nitrogen test mode" and "Nitrogen + helium standard test mode" for customers to choose according to their actual needs;

The "Nitrogen + helium standard test mode" in line with international standards can ensure the accuracy and consistency of results, and is easy to operate;

For samples that can adsorb helium at low temperatures, helium gas is not suitable for the determination of free space. The "Single nitrogen test mode" can get the desired test results.