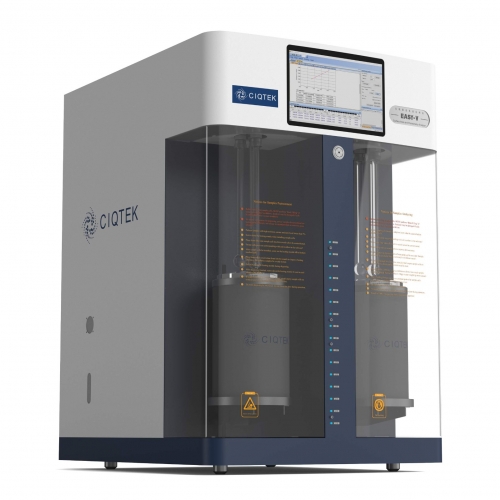

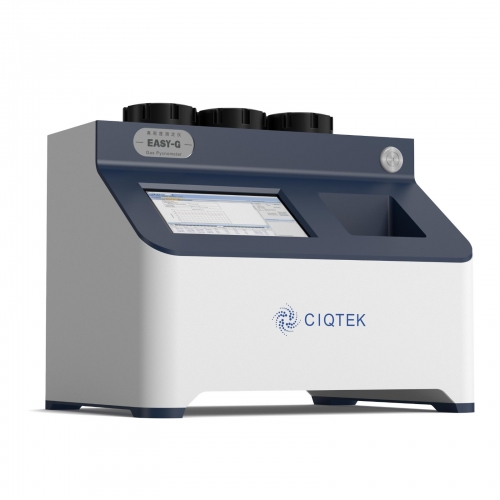

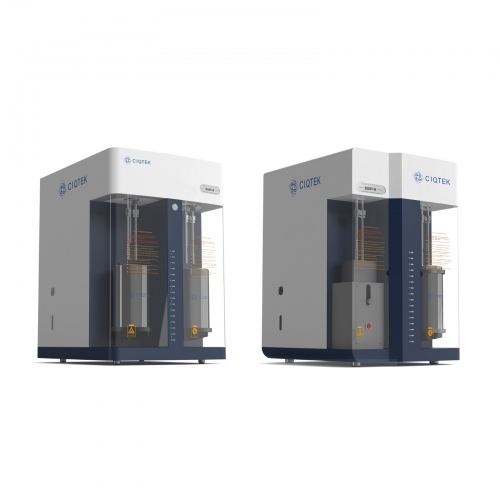

Application of Gas Adsorption Technology in Conductive Paste Industry

Conductive paste is a special functional material with both conductive and bonding properties, widely used in new energy batteries, photovoltaic, electronics, chemical industry, printing, military and aviation and other fields. Conductive paste mainly includes conductive phase, bonding phase and organic carrier, of which the conductive phase is the key material of conductive paste, determining the electrical properties of the paste and the mechanical properties after film formation. The commonly used materials of conductive phase include metal, metal oxide, carbon materials and conductive polymer materials, etc. It is found that the physical parameters such as specific surface area, pore size and true density of conductive phase materials have an important influence on the conductivity and mechanical properties of the slurry. Therefore, it is particularly important to accurately characterise physical parameters such as specific surface area, pore size distribution and true density of conductive phase materials based on gas adsorption technology. In addition, precise tuning of these parameters can optimise the conductivity of the pastes to meet the requirements of different applications. 01 Conductive paste introduction According to the actual application of different types of conductive paste is not the same, usually according to the different types of conductive phase, can be divided into conductive paste: inorganic conductive paste, organic conductive paste and composite conductive paste. Inorganic conductive paste is divided into metal powder and non-metallic two kinds of metal powder mainly gold, silver, copper, tin and aluminium, etc., non-metallic conductive phase is mainly carbon materials. Organic conductive paste in the conductive phase is mainly conductive polymer materials, which has a smaller density, higher corrosion resistance, better film-forming properties and in a certain range of conductivity adjustable and so on. Composite system conductive paste is currently an important direction of conductive paste research, the purpose is to combine the advantages of inorganic and organic conductive paste, the inorganic conductive phase and organic material support body organic combination, give full play to the advantages of both. Conductive phase as the main functional phase in the conductive paste, to provide electrical pathway, to achieve electrical properties, its specific surface area, pore size and true density and other physical parameters have a greater impact on its conductive properties. Specific surface area: the size of the specific surface area is the key factor affecting the conductivity, within a certain range, a larger specific surface area provides more electronic conduction pathways, reducing the resistance, making the conductive paste more conductive. High conductivity is critical in many applications, such as in electronic devices to ensure efficient conduction of circuits. Pore size: ...